Screen printing machine is a large equipment in the printing industry, has been widely used in our life and work, except for liquid and gas, other things can be printed with screen printing machine.The distance of the screen and the printing product is one of the important factors.In order to ensure the printing quality,operator make the adjustments of the distance.

The key technical points are as follows:

1. Screen printing machine printing process points

If the screen printing machine printing scraping pressure is high, the amount of the leaking ink is more, but the screen plate is easy to be deform, so the scraping pressure should not be high.The scratch speed is often 60 ~ 200 mm/s.Scraping speed is fast, less ink leak, but not easy to block the net.Therefore, the ink that is easy to block the net, scraping speed should be faster.

The scraping route shall be straight, oblique and curve.It shall be selected according to its flatness and graphic distribution on the bearing.When the scraping route is long and the ink consumption is large, the scraping amount of ink should be more or even scrape a layer of ink first, after scraping.

2.Judgment method of ink consistency:

Thick printing ink to through the screen plate, no screen mesh or wire drawing on the printing surface.Thin printing ink to put on the screen, the ink by its own weight can reach through the mesh but not dripping .When the printed lines are thin, the ink should be thin, otherwise, it should be thick.

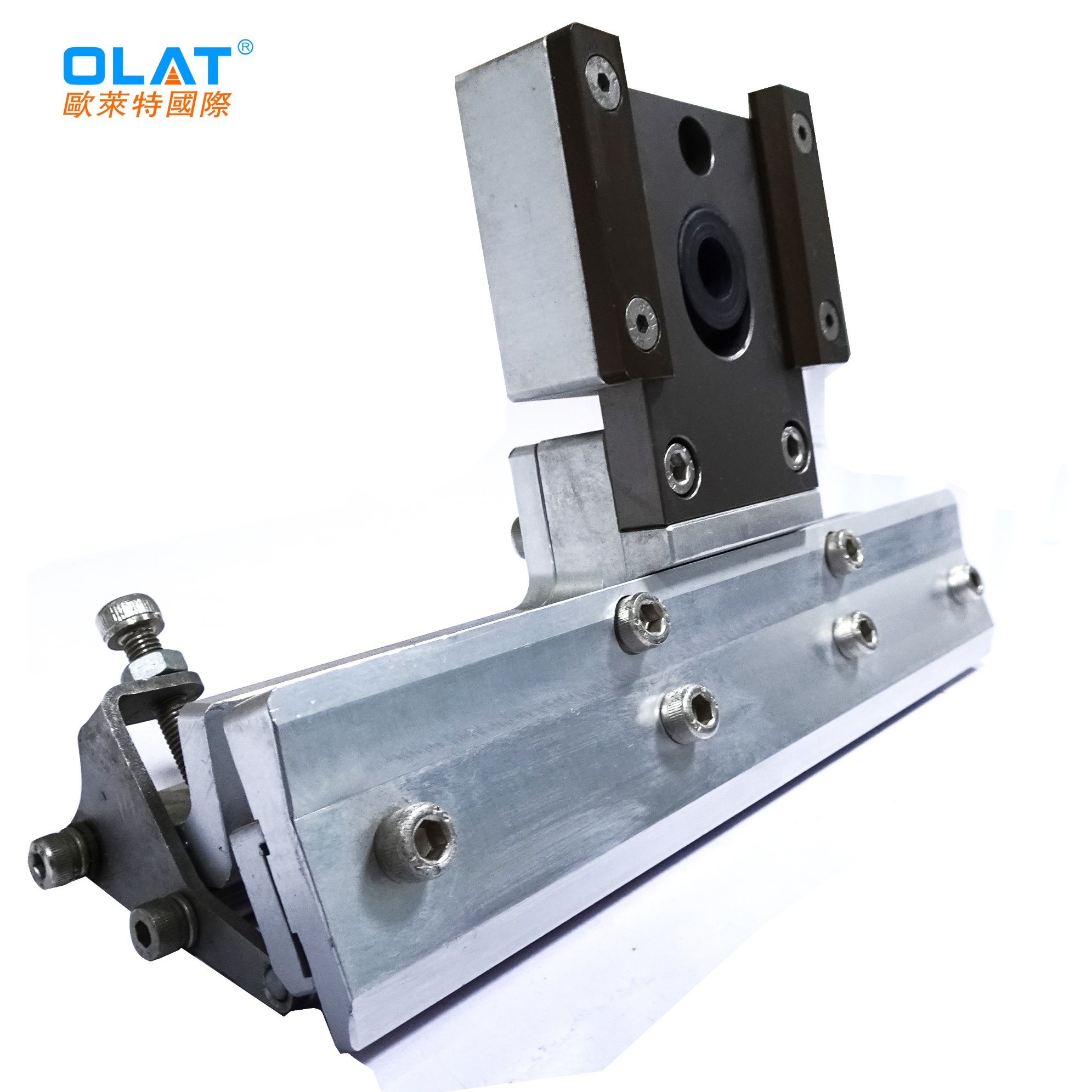

3.Select the printing scraper

The material of the scraper is mostly polyurethane.Polyurethane rubber scraper has good wear resistance, solvent resistance and return elasticity.Its hardness is selected from 60~80 Shaw Run.The bearing material with large network plate tension and good surface flatness should choose a scraper with high hardness.On the contrary, you should choose the low hardness.When printing on a curved surface, low-degree sphere or poor flatness (locally protruding) bearing, the scraper width should be narrow but not wide.

4.Screen plate selection before printing

The quality of the silk cloth is uniform in diameter, and the number of mesh is stable.The general selected mesh is 450~500 mesh.The bearing material with high fine line and ink fineness and poor absorption should choose the network version with high number of mesh items, otherwise, the network version with low mesh number should be selected.The position and size of the text and text on the screen plate shall be determined according to the structure, size of the bearing object and the position of the drawing and text on the bearing material.If the design is not good, it will affect the quality of the silk screen, and even can not be the silk screen.In addition, the same object is printed on the text, the best printed with a web print.If divided into more than two web plate printing, the process will reduce the qualified rate of silk printing.