Pad printing belongs to one of the special printing methods.It is able to print text, graphics and images on irregular products and it is now becoming an important specialty printing.For example, the text and patterns on the surface of a mobile phone are printed in this way, as well as computer keyboards, instruments, instruments and many other electronic products, which are printed by pad printing.

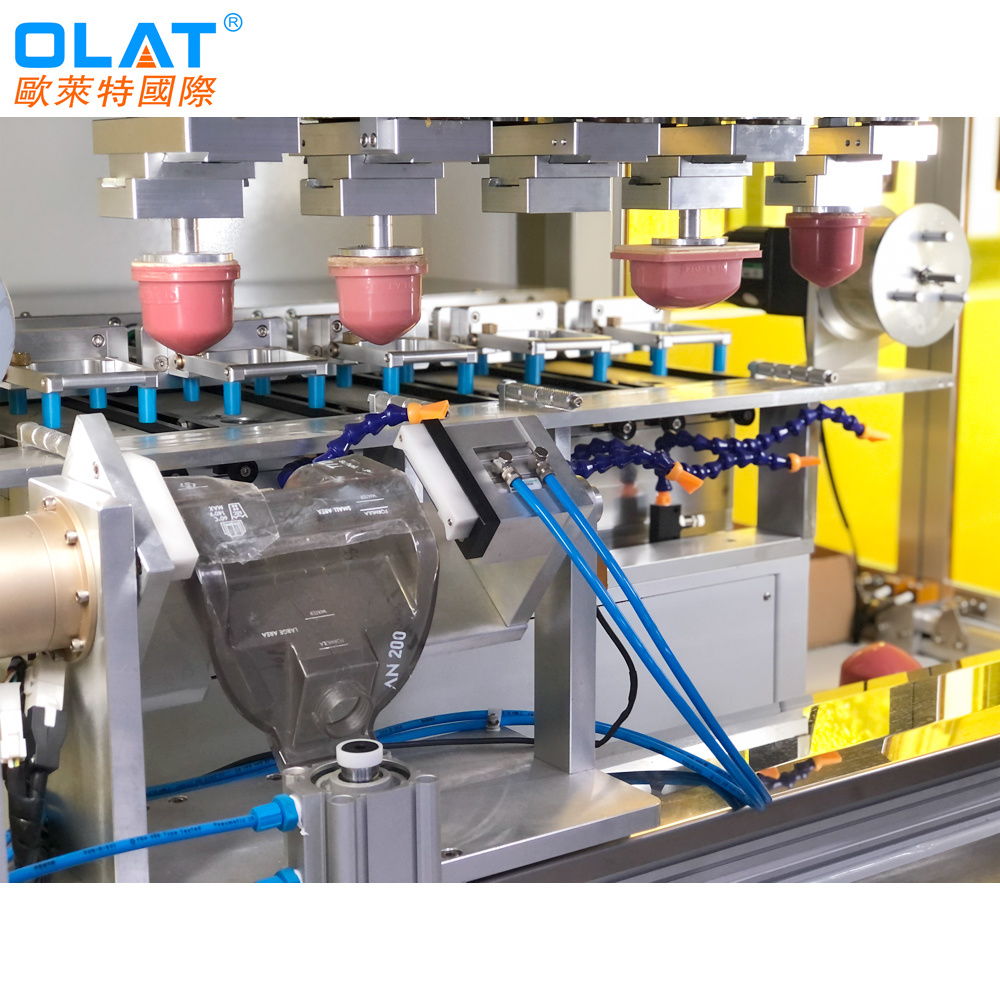

Principle: The printing machine is mainly composed of printing device (including ink supply device), ink scraper, printing rubber head (it is generally silicone material) and working table.With the help of the rubber head that can be deformed, the surface of the rubber head does not contain design; the required design should first be baked and etched into the printing plate, ink is then applied to the etched design on the printing plate,scrcrape the ink in non-graphic areas from the plate with a hard scraper,let the rubber head to dip ink in the printing plate and lift the rubber head,transfer the ink on the surface of the rubber head to the surface of the product.

Types of the pad printing machine:

Transmission mode: manual mechanical printing machine, electric printing machine, pneumatic printing machine

Printing color number: single color transfer, double color transfer, multi-color transfer (shuttle multi-color, conveyor belt multi-color transfer)

Ink storage mode: inkwell pad printing, inkcup pad printingBecause the pneumatic printing machine has simple structure, convenient operation and smooth movement etc. characteristics, it is widely used at home and abroad, and is the mainstream of printing machine.

Inkwell type printing machine is a more commonly used form.

Pad printing machine with ink cup, ink is closed inside the ink cup. It is relatively environmentally friendly, and can ensure the stability of ink in the printing process.