Simply put, CCD visual inspection, CCD visual inspection system is to use industrial cameras instead of human eyes to complete functions such as identification, measurement, positioning, and judgment. Visual inspection refers to converting the captured target into an image signal through a machine vision product, transmitting it to a dedicated image processing system, and converting it into a digital signal according to pixel distribution, brightness, color and other information.

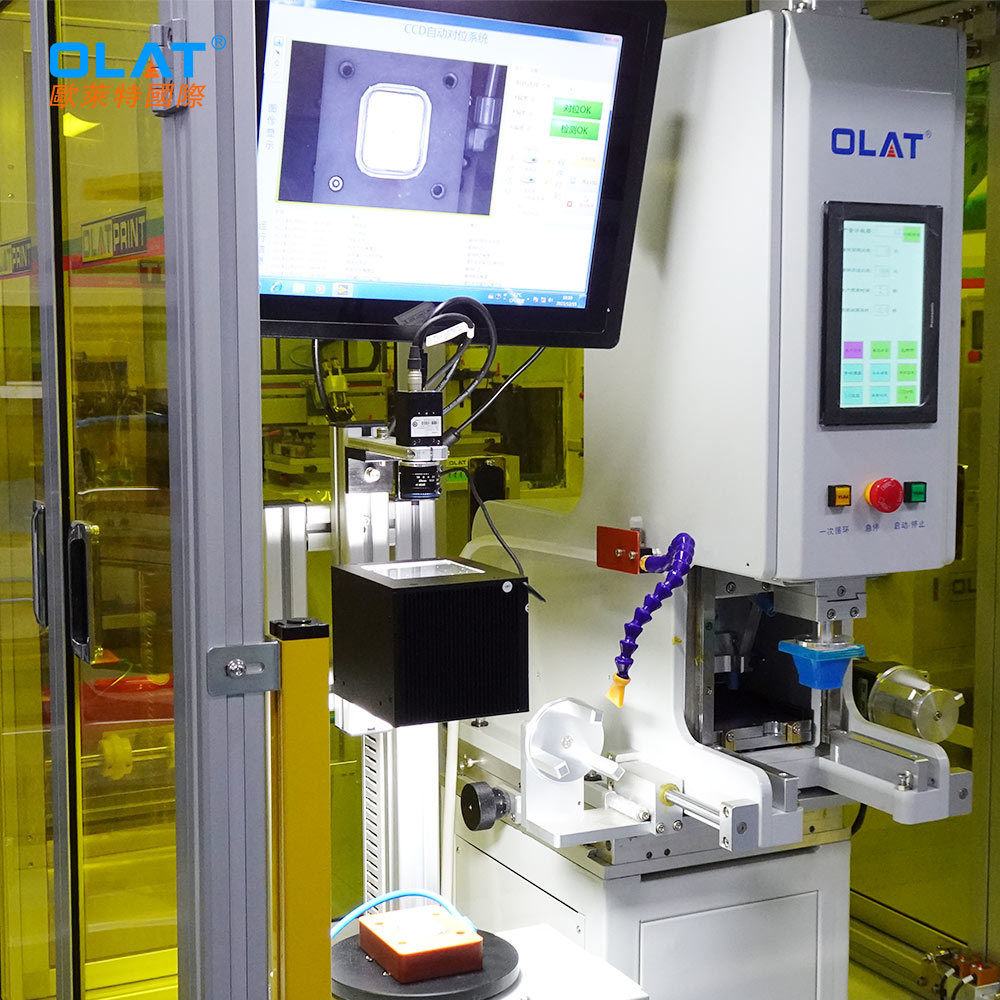

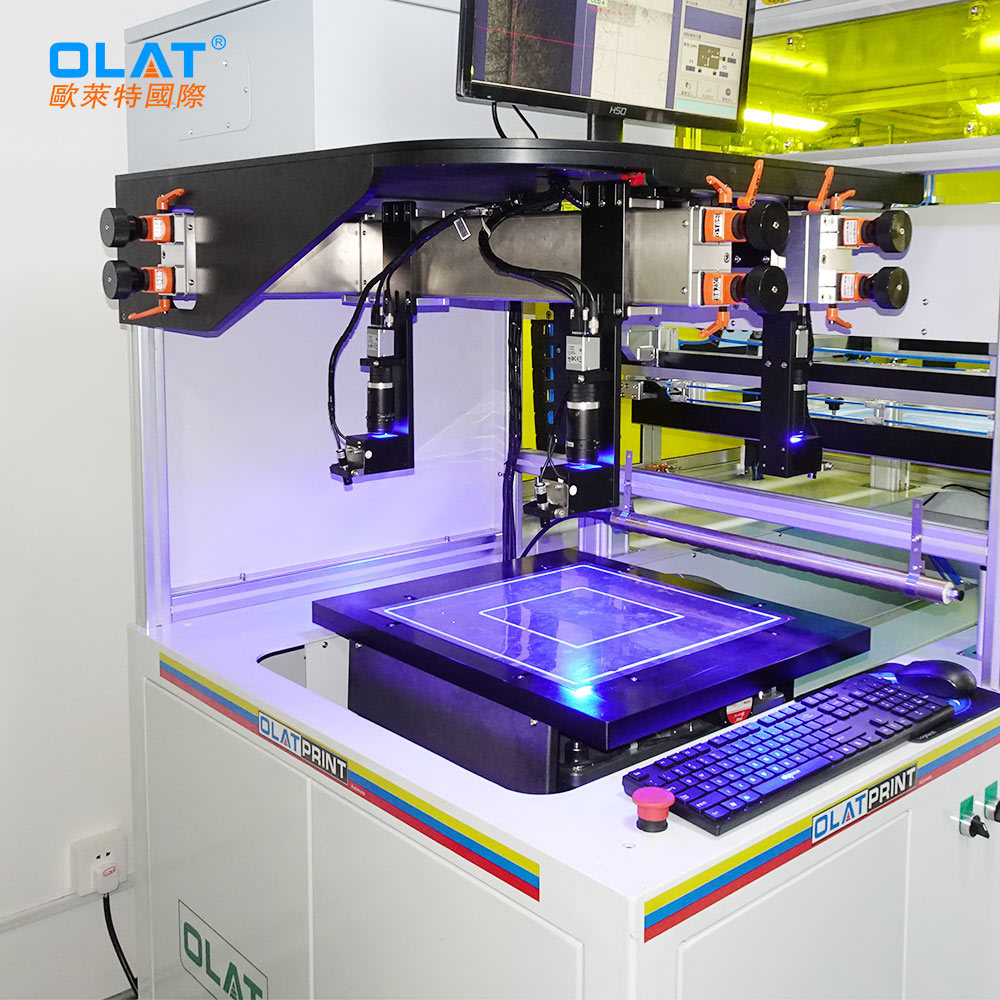

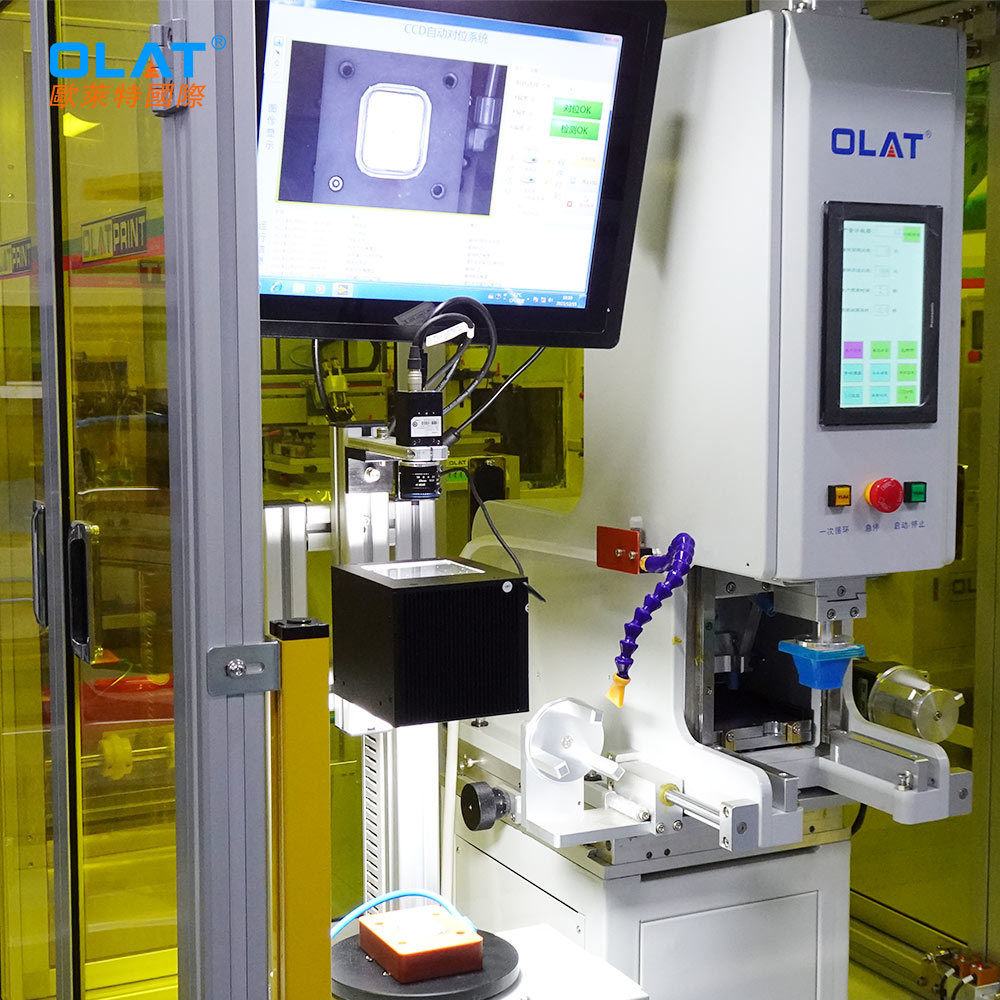

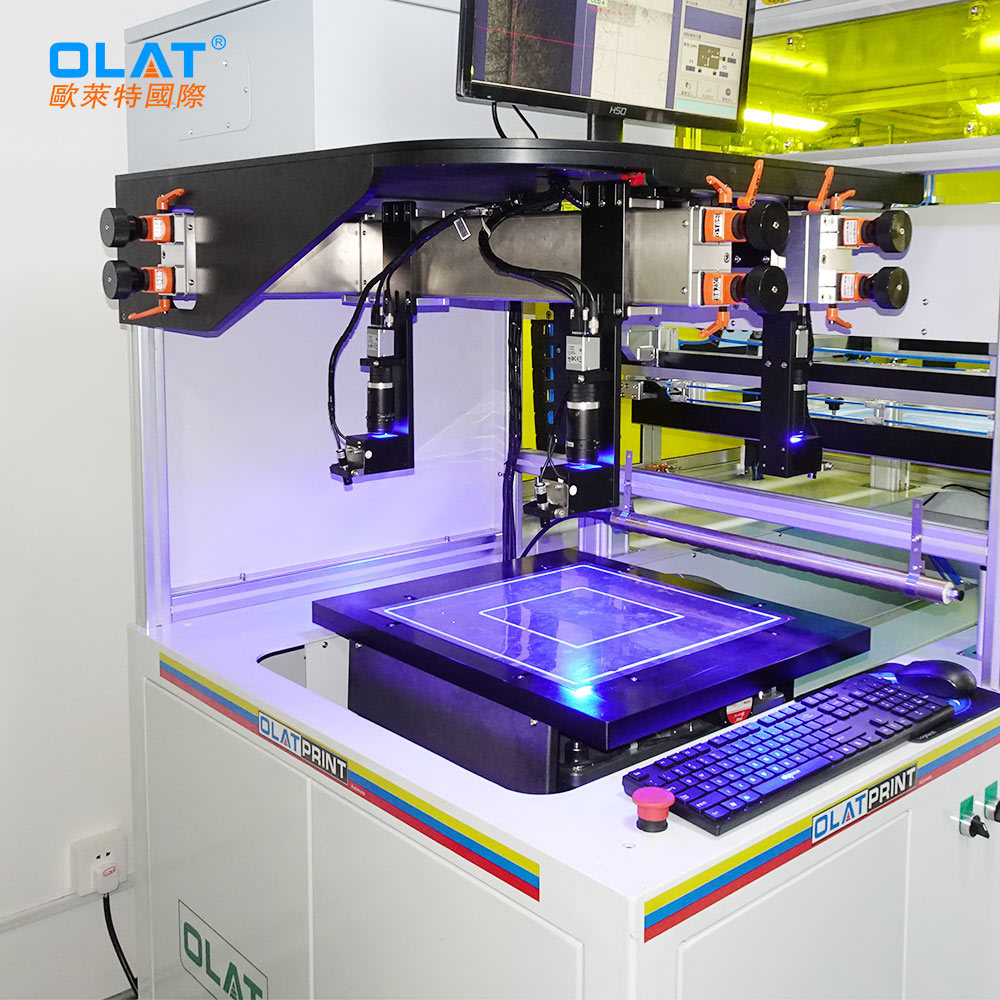

At present, machine vision inspection is mainly divided into three categories: main function, detection technology, and installation carrier: ??1. Machine vision inspection is classified according to functions: positioning, defect detection, size measurement, counting/omission detection, feeding and blanking Wait.??2. Machine vision detection is classified according to detection technology: three-dimensional machine detection technology, mottled detection technology, scale measurement technology, OCR technology, color recognition technology, etc.??3. Machine vision inspection is classified according to the carrier of its device: online inspection system and offline inspection system.??Machine vision inspection equipment has the characteristics of non-contact, high precision, automation, etc. Compared with image processing systems in the general sense, machine vision emphasizes accuracy and speed, as well as reliability in industrial field environments. Machine vision is suitable for measurement, inspection and identification in mass production processes, such as: part assembly integrity, assembly dimensional accuracy, part machining accuracy, position/angle measurement, part recognition, feature/character recognition, etc. Machine vision detection technology can be used, which has a very huge market development space. CCD visual detection automatic detection equipment for material shortage, CCD can be called CCD image sensor. CCD is a semiconductor device, a chip that can convert optical images into digital signals. CCD vision is more commonly understood as a camera equipped with a CCD chip. This camera is used in industrial production to form a set of equipment with detection functions, which is called visual inspection equipment.

So what conveniences does CCD automated testing equipment bring to enterprises???1. Automatic testing, improve work efficiency, and realize 360-degree real-time testing of products; ??2. Improve testing accuracy, unify testing standards, eliminate individual differences in manual testing, and ensure that The quality of each product is qualified; ??3. The average cost of one-time investment is far less than the labor cost, and it can also solve the problem of difficult recruitment of enterprises; ??4. Information storage records can summarize and analyze data, which is convenient for front-end processes to find problems and provide suggestions for subsequent processes .