Pad printing is a very simple printing process, which transfers the printing design from the plate to the surface of the printing products by rubber head.Pad printing machines can be used for flat product surface or various molding printing, such as glass, plastic, metal, watches, electronic, optical, and etc.Its main feature is the irregular abnormal concave and convex surface printing, which is difficult or even unable to complete with other printing methods, and pad printing can be easily completed, and can achieve multi-color exquisite printing.This is an ideal way for printing on the surface of instruments, equipment and some small products.In addition, its printing is stable and continuous, even if a long time printing, printing accuracy will not change, can be continuous multi-color printing.

Classification according to color the printing machine mainly has single color, two colors, four colors, six colors and eight colors.From the degree of automation it is divided into semi-automatic type and fully automatic type.There are also printing machines with a PLC system, which further increases the degree of automation.Here mainly from the overall structure of the printing machine and some local key components of the current market on the main printing press analysis.

1. The semi-automatic pad printing machine

This type of pad printing machine structure is the simplest one, the operator puts the product on the workbench, step on the foot switch, after the automatic printing, the operator will remove the product from the workbench.Of course, this kind of machine generally will not appear in the relatively large printing enterprises, in many small enterprises and small printing enterprises are more applications.Its disadvantages are very obvious, such as low production efficiency, but its easy to operate, small investment, so it is still very active in the market.

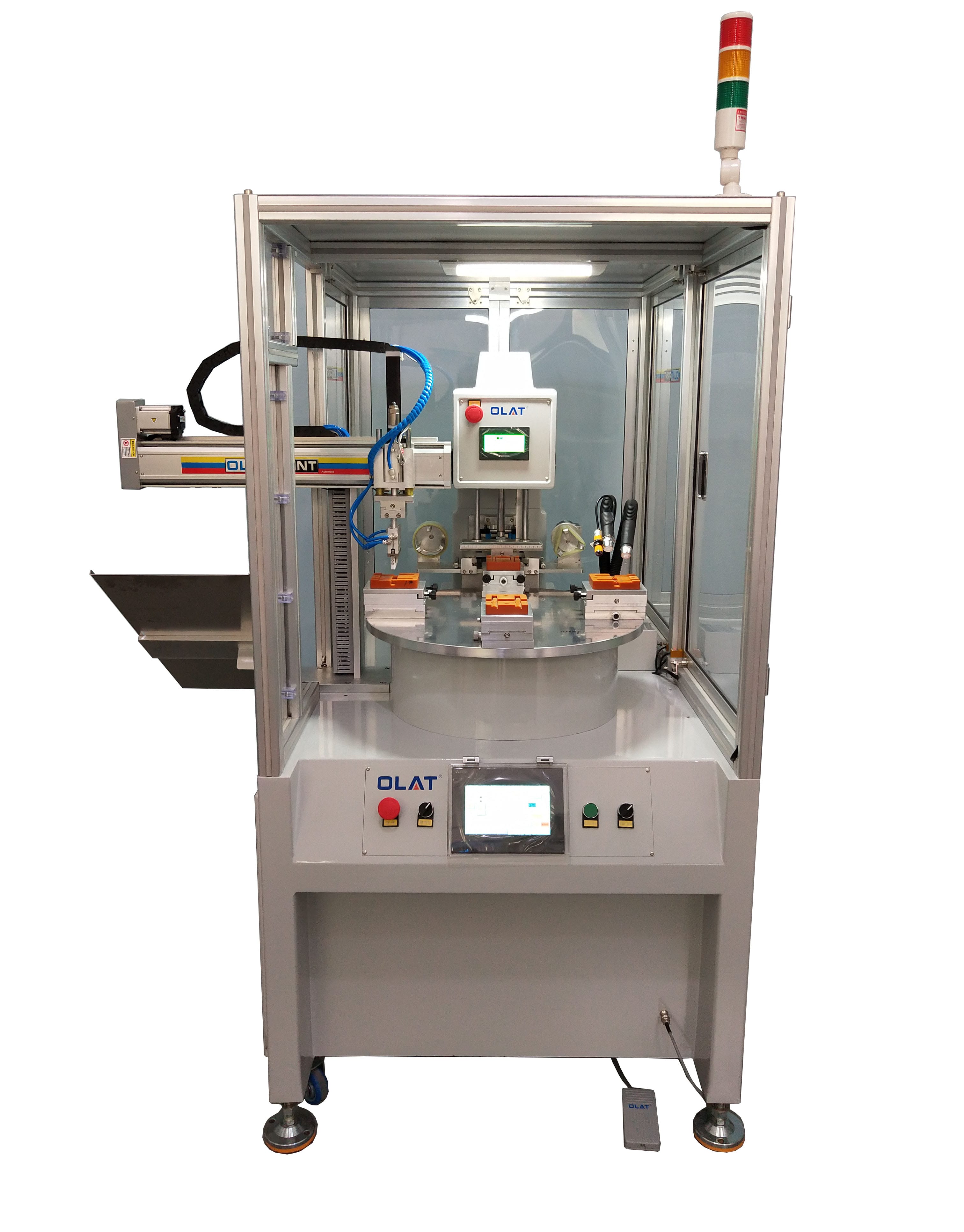

2. Automatic pad printing machine

Automatic printing machine printing speed is fast, simple manual, improve efficiency, our company has a strong research and development team, professional designers, can combine the customer requirements of the products to be printed, special design to meet the best results.