Pad printing belongs to one of the special printing methods, screen printing is one of the four printing methods in China, it is, together with lithography printing, convex plate printing, gravure printing is called the four printing methods, is also one of the special printing methods, so what is the difference between these two printing methods?The following article shares the differences between screen printing and screen transfer printing:

Silk printing process is the ink through the mesh version of part of the mesh after the leakage of printing on the seal, the rest of the mesh mesh is blocked, the ink through.When printing, the ink is poured on the web plate, under the action of no external force, the ink will not leak through the mesh to the bearing, and when the scraper scratches the ink at a certain pressure and tilt Angle, it is transferred to the bearing below through the web plate to realize the reproduction of the image.

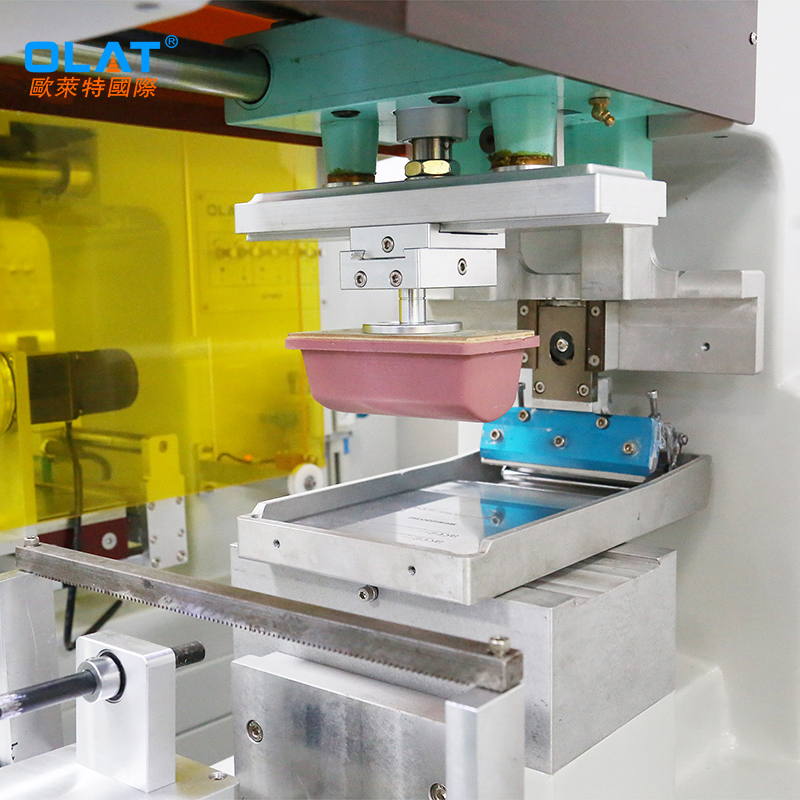

The basic principle of pad printing is in the printing machine, first put the ink into the carved text or pattern steel plate, and then through the ink to print to the rubber, and then use rubber to print the text or pattern to the surface of plastic products, it is best through heat treatment or ultraviolet light irradiation methods to make the ink curing.

01Silk printing characteristics

Wide scope of application

Because the printing plate is made of silk screen, soft and flexible, so the seal can be printed whether flat or curved, hard or soft, large or small.In addition, the screen printing can also be printed on fragile and deformed seals due to small pressure.

Thick ink layer and strong covering

Silk printing ink layer thick, is incomparable to other printing methods.If the following background color is covered with white, the ordinary printing method needs to be printed in the same place 3 to 4 times, and the silk printing as long as once can be completed.Silk printing ink layer thickness is generally 20 microns, special thick film printing up to 100 microns, the thinnest can also has 6 microns.So the silk printing ink layer is thick and the adjustable range is large.

Strong three-dimensional sense

Due to the thick ink layer, so the effect of imitation prints and reproduction oil painting is very realistic, and its color is much more than offset printing.However, in the printing of fine patterns, the reproduction effect is limited.

Good light tolerance

After incorporating light-resistant and fluorescent pigments into the ink, the print pattern can be permanently shiny without air temperature and sunlight, and can even glow at night.Therefore, silk screen products are suitable for outdoor advertising, signage, etc.

More applicable ink

There are water, oil, solvent, etc., and even can use slurry, paste, powder.Therefore, silk printing ink is collectively referred to as printing material.

Large printing area

In terms of printing area, general offset printing, convex printing and other methods are far less limited by mechanical equipment than silk printing.The maximum size of the screen print is 3M * 4M or even larger.

The printed plate has a large scalability

The characteristics of the screen material determine that the printing plate will have a large scalability.When used in large quantities, easy prints can affect the effect of replication.

02 Pad printing characteristics

Pad printing is mainly through the rubber head to complete the transfer process, so the printing process is limited by the performance and shape of the rubber head.The glue head has the characteristics of elasticity, arc shape and not infinite size.

In principle, it can be said that the shape can be printed.Therefore, the applicable surface of printing is very wide, but the printing range of printing from the characteristics of the general outline, can not be printed large area of patterns.

A wide range of applications

In line with the requirements of beautiful appearance, good quality, so that the printing is more luxurious.Its application field is developing so fast, that we have to face more and more printing products every day.Such as decorations, clocks, glass bottles, labels, etc.; toys, stationery, light box advertising, etc.

Direct printing

On the special pad printing machine, use the rubber head to dip the ink from the plane steel plates, and then by the rubber head to transfer the ink text to the printing product.

Has the many advantages of silk printing

Such as the wide adaptability of the bearing material, low cost, can use the vast majority of online printing ink.But moving printing is mostly used for small plane, concave and convex surface graphic printing, printing is flexible and easy to set color.

A perfect match for screen printing

Can print the plane such as flat, spherical, curved, into Angle or concave, can be multi-color wet wet printing on the object, without drying between color.

03 The principle of difference between pad printing and screen printing:

principle

Pad printing: through the action of the rubber head to transfer the pattern engraved on the steel plate to the workpiece, similar to the seal silk printing in daily work

Screen printing: pressure passing through plastic scraping,perenetrate ink from the mesh onto the product, then printing design is on the product.

Printing area

Pad printing: the printing area of pad printing has a certain limit.

Screen printing: the printing area is basically unlimited, consumables (screen plate) cost is low, and can be reused.

Product appearance

Pad printing: there is no limit on the shape, the plane, the curved surface, the wave surface, as long as the rubber head shape is accessible place can be printed.

Screen printing: the printing surface of the product shall be flat, plain or regular surface.